Slump Test:

Slump test is the most widely used method to determine workability of concrete mix in the lab or at the site. This test is simple to perform and requires a simple apparatus. Slump test is preferred for medium workability concrete mix and is not suitable for very wet or very dry concrete mixes. Although it does not measure all the factors contributing to the workability but is very useful on site to judge the relative variation in the quality of concrete from batch-to-batch.

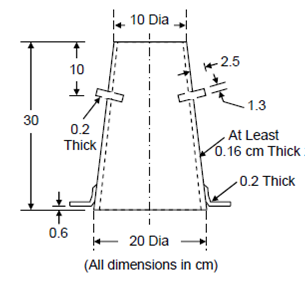

In this test, the metallic mould in the form of frustum of cone of the standard size, as shown in Figure 2, is used. The concrete mix is poured in the mould in layers in specified manner. Every layer is compacted in standard manner with the help of tamping rod. After filling the mould with the compacted concrete the top surface of the concrete is flushed with the top of the mould. Now, the mould is smoothly lifted vertically upward so as to leave the self-supporting concrete mass behind.

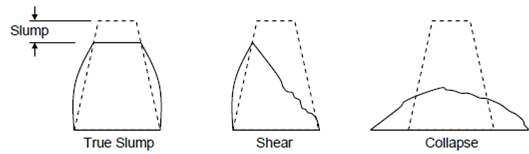

Immediately after removing the mould the concrete mass gets subsided. The height (in mm or cm) by which the concrete mass subsides is called the slump of concrete, which represents the workability. The pattern of slump may be any of the three forms as shown in Figure 3. The slump can be measured only in the case of true slump. Many are the slump better is the workability of concrete mix. The shear slump indicates that the mix is not properly cohesive and has a tendency to segregate, therefore concrete is not appropriate for placement. The collapse slump indicates that the concrete mix is very wet or lean. The excessive wet concrete mix will have flowability, while lean mix will have less cohesion and inadequate consistency.

Figure: Slump Test Apparatus

Figure: Various Forms of Slump

By observing the slumps of different batches of concrete mix one can judge the variation in the proportion of ingredients from batch to batch. For example, greater slump indicates the increase in water content; if true slump turns to shear slump it indicates that the quantity of cement is reduced or mix is harsh; similarly the collapse slump indicates sudden increase of water content in the concrete mix. In view of the above, the test is very useful in ensuring the quality control on the mix proportion.