Flow Test:

This method is more attractive for the flowing concrete or for the concrete with super plastisizers. In addition to measuring the workability by this method, one can also closely observe the consistency, cohesiveness and segregation characteristics of the concrete mix.

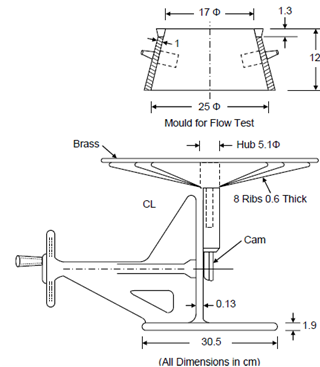

The details of test apparatus, used in this method, are shown in Figure. The shape of the metallic mould used in this method is similar to that used for slump test. To start with, the metallic mould is placed on the center of the flow table.

Figure: Flow Test Apparatus

The concrete mix is poured in the mould in layers by compacting each layer in standard manner through a tamping rod. After flushing a concrete at the top of mould the mould is smoothly lifted vertically upward. The compacting efforts are then provided to the concrete mould by raising and dropping arrangement of the flow table in standard manner.

Now, the flow of concrete is measured by measuring the spread diameter of the concrete mix at least in about 6 directions and the percentage flow is determined by the following formula:

Low (%) = (Spread diameter in cm - 25)/25 ×100

where, 25 cm is a fact base diameter of the concrete mould before compaction.