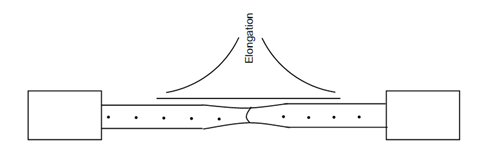

Distribution of Elongation

Figure shows how the plastic deformation is distributed along the length of the specimen. Different gauge points have been illustrated marked on the specimen. It can be seen that by choosing any pair of gauge points, equidistant from the centre, one may arrive at a value of percent elongation which will differ from that obtained by choosing a different pair of gauge points. This example shows that percent elongation is not a unique quantity for a material but may vary with gauge length. For this reason gauge length is standardised so that comparison of ductility between two materials may be made consistently. For cylindrical specimen gauge length of five times the diameter is chosen as a standard. But in any case percent elongation is described with gauge length on which it has been calculated.

Figure: Distribution of Elongation along the Length of Tension Specimen

The value of percent elongation may be obtained from diagram as the strain at the time of fracture multiplied by 100. More practically, the two pieces of specimen after fracture may be placed together touching at fracture surface and the distance between gauge points noted to measure final length Lf. Then,

% elongation = (L f - Lo / Lo ) × 100

The % reduction in area of cross-section is also used as a measure of ductility. It is defined as:

% reduction in area = (Ao - Af)/ Ao × 100

Where A and L represent the area of cross-section and length respectively, f and o are respectively the suffixes to denote final and original values.

It may be understood by above description that both % elongation and % reduction in area would define the local ductility of the material. Maximum uniform strain, which is the strain just before necking begins or the strain corresponding to ultimate stress, May sometimes be used to indicate the ductility of a material.

Ductility is an important property of material which governs its ability to be deformed in such processes as drawing, forging and extrusion. Adequate ductility ensures that the materials during these processes will not fracture. All associated property by virtue of which sheets can be rolled from material is termed "malleability".