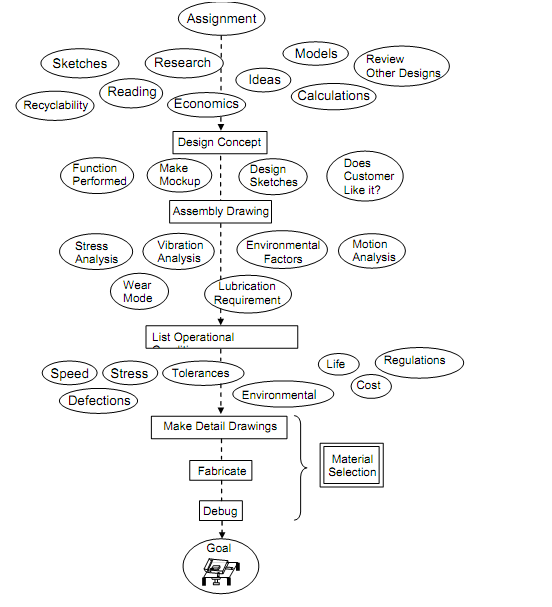

Role of Material Selection in the Design Process

The task of the most of the designers is to design a product to perform some specified function. The design assignment may come from an operating department, or the designer can formulate his or her own proposal. Whatever the case, the assignment shall usually be something like the following: Assume it is required to design a device to move part X from a hopper and assemble it in the part Y. To start with you should specify a goal for the device to be designed, build up the design followed by building the device so as to run satisfactorily, be economical to operate with high degree of reliability and long service life.

Step 1 is to sit and think about the problem (this "thinking" step must be done with a pencil in hand). Ideas must be produced, which are pursued with, literature, searches models, sketches, discussions with the customer, and the like.

If the thinking step is productive, a design concept might take shape. A way of putting part X in part Y becomes apparent. Sketches are made. Sizes are established.

Drive and actuation systems are envisioned. Questions should be asked. Are all of the desired functions are possible to attain? Is the probable cost within the project limits? Are the desired speeds or production rates possible? The device must start to get in the mind of the designer.

Step 3 is to make an assembly drawing to discover if the design concept works on paper or on the computer. If it does not, it might be essential to return to the beginning. Once an assembly drawing is complete and a motion analysis mentions that parts move as they are assumed to and do not hit each other, it is time to obtain into hard-core engineering analysis, e.g. stress, acceleration analysis, vibration and the like. This is not even too early to think of such things as wear mode, operating environment, lubrication and the influence of component failures.

The next step is to establish all of the operational requirements of each of component in the device. Which parts has to be hard? How much deflection may be tolerated in this shaft? What flatness is required on the base plate? Is corrosion a problem in the loading mechanism? May this arm tolerate any wear? What is the bending stress in this shaft? These are the types of factors that should be established.

Once the designer has firmed up in her or his mind the needs of each part, it is time to make detail drawings. Material selection is a key part of this step in the design process. A set of drawings should be produced that illustrate the dimensions, shape material of construction and applicable treatments or special sequence.

The last step in the procedure is to fabricate the device, debug and put in service. Materials enter into these steps in fabric ability & substitution of new materials for the parts that did not make it through debugging. The designer must start thinking about materials of construction quite early, and more significant, effective material selection is predicated on knowing the operational requirements of every part. You merely cannot select a material for a part without knowing what that part should do in service.

If an engineering assignment needs purchase of a piece of machinery or subcontracting of a structure or facility, some steps in the design process shall be different. Rather than assembly and detail drawings, the designer shall probably write design specifications. Material selection would be a part of these specifications. While vendor proposals are attained, they are matched to the established specifications and once again material selection becomes vital. The vendor, for instance, wants to substitute gray cast iron for the pump housing that you specified to be CF-8 cast stainless steel. Should you permit it?

Therefore, material selection is a part of the engineering process whether you design the machine or somebody else does. All of the factors that would go into your own design should also be considered when evaluating someone else's design and it is your responsibility to make sure that the equipment functions satisfactorily. If the gray cast iron corrodes through in six months, it is your fault, not the pump manufacturers. You bought the equipment, and it is the buyer's responsibility to recommend the purchase of something compatible with the intended service environment.

Figure 3: Role of Material Selection in the Design Process