Master Production Schedule (MPS):

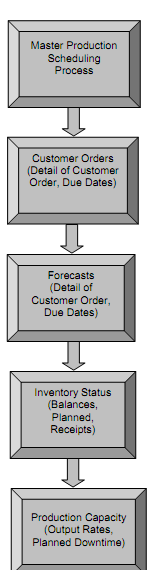

The Master Production Schedule (MPS) is a line on the master schedule grid that reflects the anticipated building schedule for those items assigned to the master scheduler. The master scheduler arranges this schedule, and in turn, this becomes a set of planning numbers that drives material requirements planning. It depicted what the company plans to generates expressed in specific configurations, quantities, and dates. MPS is not a sale item forecast that represents a statement of demand. It should take into account the forecast, the production plan, and other significant considerations such like backlog, availability of capacity, availability of material, and management policies and goals. The basic structure along with different component pertaining to MPS system is shown in Figure

In aggregate planning operations managers develop medium-range plans of how they shall produce products for the next several months. These plans contains necessary information required to manufactured the products such as amount of labour, subcontracting, and other sources of capacity to be utilized. It also engages operations managers to develop short-range production plan for the production of finished products in next numerous weeks.

Figure: Basic Structure of Master Production Schedule