Resource Scheduling:

There is always a scheduling capability in the heart of the manufacturing system that concentrates on the resources (that means the plant and equipment required to convert the raw materials into finished goods). For this cause the initials 'MRP' now mean Manufacturing Resources Planning. The benefits of this development are that detailed plans can be implemented to the shop floor and may be reported by operations, which put forward much tighter control over the plant. Moreover loading by resource means that capacity is taken into account. The problem is that capacity is only considered after the MRP schedule has been developed. It can turn out that insufficient time was permitted within the MRP schedule for the individual operations to be completed.

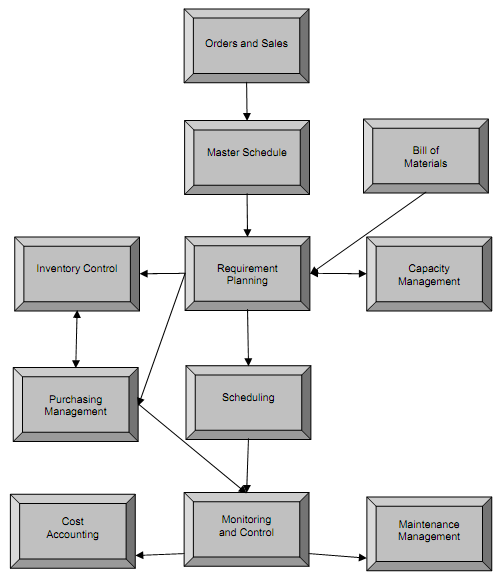

Figure: An Outline of the Element of MRP II System

In general, software packages are made that offer a variety of batching rules.

Three of the more vital batche rules are 'Lot for Lot', 'EBQ' and 'Part Period Cover'.

- Lot for Lot batches means batches that match the orders. Thus if a company is planning to make 10 of Product N followed by 20 of Product M, then the batches during the process shall match this requirement. If both N and M need two of a certain sub assembly then that shall be made in quantities of 20 of N and 40 of M. It is the batching implicitly followed in basic MRP.

- EBQ stands for Economic Batch Quantity. The batch size is computed by a formula that minimizes the cost through balancing the set up cost against the cost of stock.

- Part Period Cover means forming batches whose size cover a fixed period of demand. A policy of generating a week's requirement in one batch is an example.