Methods of Maintenance

Different philosophers have classified the maintenance methods in numerous ways of which the following is the most comprehensive.

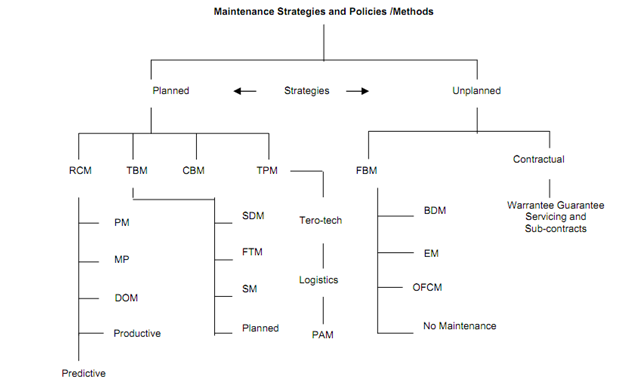

Figure: Classification of Maintenance Policies/Strategies

To understand various maintenance methods, let us discuss under two heads viz. planned and unplanned strategies. The planned strategies are designed on basis of certain maintenance characteristics such as number of failures or frequency of failures or durations of failures, time between failures, time to repair, machine condition, machine life, reliability, maintainability and availability and so on. Summing up, all these, we can classify four philosophies in planned strategies. These philosophies/techniques are Reliability Centered Maintenance (RCM), Time Based Maintenance (TBM), Condition Based Maintenance (CBM), and Total Productive Maintenance (TPM). Under unplanned strategies we find Failure Based Maintenance (FBM) and Contractual Maintenance (CM). These are further classified into various methods depending on their dominant features.

Failure Based Maintenance (FBM)

This includes Breakdown maintenance (BDM), Operate to Failure and Corrective Maintenance (OFCM), Emergency maintenance (EM).

Contractual Maintenance

Service Contracts, sub-contracts, Maintenance provided by the OEM, Maintenance in the warrantee/guarantee period, etc.

Reliability Centered Maintenance (RCM)

Maintenance Prevention (MP), Design out Maintenance (DOM), Productive Maintenance and Predictive Maintenance are included in this.

Time Based Maintenance (TBM)

This includes Preventive maintenance (PM), Scheduled Maintenance(SM), Shutdown Maintenance (SDM) and Planned maintenance.

Condition Based Maintenance (CBM)

Dynamic Predictive Maintenance (DPM) or Condition Based Maintenance (CBM).

Total Productive Maintenance (TPM)

TPM, Tero-technology, and Physical Assets Management (PAM).