Procedure for Reliability Centered Maintenance Modeling and Analysis

After distinguishing between the repairable and non-repairable items, the reliability study can be established as it suits to the requirements. The most useful and universal procedure of reliability centered maintenance modeling for repairable equipment is narrated here. The field data is collected for the equipment categorized under repaired items in the form of Time between Failures (TBFs) and Time to Repair (TTRs). The data inconsistencies and errors are removed and the refined data is analyzed by both types of models viz. Graphical and Analytical models. However, more importance is given to Graphical method since they can give more and simple understanding and can be easily reproduced. The graphical tests such as Eye-Ball analysis, Cumulative Plot test and Serial Correlation determine the presence of Trend.

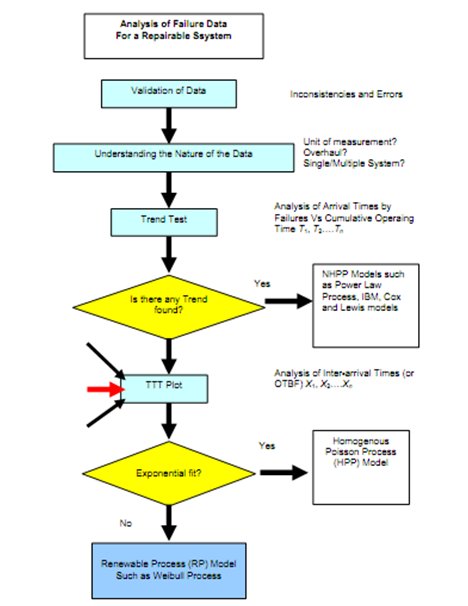

The machines, which exhibit presence of strong trend, are further analyzed and fitted into Non- Homogeneous Poisson Process (NHPP) model. Power Law Process (PLP) model, one of the most popular & commonly used NHPP models can be used for such study. If there is no trend, it confirms the independently and identically distributed (i.i.d.) assumption. The values obtained can be checked with some analytical tests such as Laplace test. The machines free from trend are further graphically analyzed through Total Time on Test (TTT) plots. The exponential fit that confirms Homogeneous Poisson Process (HPP) models can be known from this analysis, otherwise can be categorized as Renewable Process (RP) model which is in accordance with Weibull pattern. The Goodness of Fit (Analytical) tests can confirm this; otherwise can identify the actual distribution from which the data has come. Thus reliability characteristics and maintenance schedules can be estimated. Further, their reliability growth plots can also be drawn to estimate the improvements. Algorithmically it is explained as given below and followed by a flow chart in Figure.

Figure: General Procedure for Analysing Failure Data of Repairable System