Metal Cutting

In metal cutting, excess material is removed by controlled chip-forming processes. The relative ease or difficulty with which the material can be removed is termed as machinability. An alloy of good machinability can cut at higher metal removal rates with acceptable tool life and will give better surface finish at lower cost. Some processes are most suitable for producing tight tolerances and finer surface finish, but the general guide lines should be interpreted with caution: in any given process, a hard, leaded brass will be easier to cut and will give better finish than a soft copper or a hard super alloy. Because the shape is generated by removal of excess material, there is basically no limit on section thickness that can be produced except as influenced by deflection of the parts under cutting forces. Because heat generation increases with cutting speed and power consumed, the choice of tool material has decisive influence on the speed of machining.

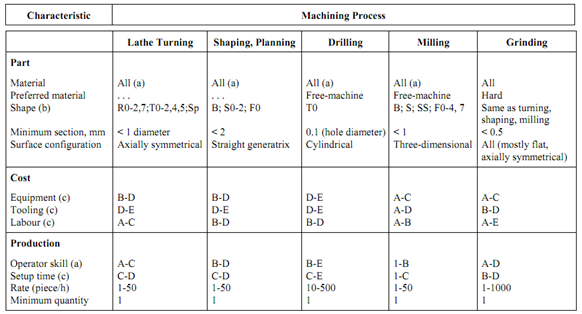

Table 4: General Characteristics of Machining Processes

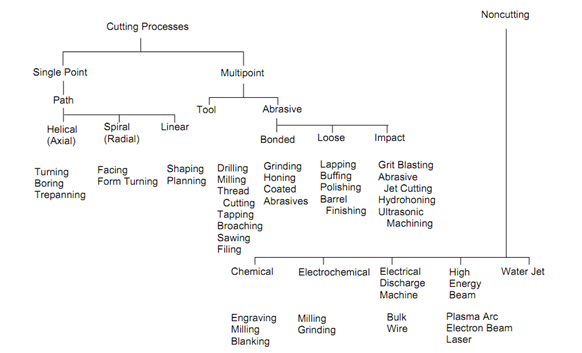

Figure 8 : General Classification of Metal Removal Processes