Minimum Cost Per Component Criterion:

Procedure to achieve optimum cutting speed and optimum feed rate for minimum cost per component involves the following steps :

A. Write the total cost equation (Eq. (10.1)) in terms of the two variables (f and V) only (depth of cut is assumed to remain constant for a single pass case).

B. Differentiate the total cost equation with respect to cutting speed V and feed f separately, and solve them.

C. From the equations obtained in Step (ii), derive an equation for tool life for minimum cost per component.

D. Consider various necessary constraints and modify the selected optimum machining conditions.

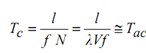

The values x, Tl, Td and y in Equation (1) are found from the cost data and standard times hand book. Since the depth of cut is usually fixed, the speed and feed must be chosen to minimize the cost per component. Machining time (for single pass) Tc is, generally, approximately equal to the actual cutting time Tac , and is found from

---------------------(9)

---------------------(9)

where,

l = distance traveled by the tool in making one turning pass (m),

N = spindle speed (revolutions per second),

V = cutting (or peripheral) speed (m/s), and

λ = 1 / πD.

(D work diameter).