Machine Tool Speed and Feed Restriction:

The final choice of cutting conditions must satisfy a number of restrictions. The method of selecting the cutting conditions for each restriction is now considered. In case the optimum feed (fopt) is not available on the machine tool, select the highest feed available (closest to the fopt) on the machine tool, and then re-calculate the optimum value of velocity from Eq. (12) corresponding to this selected feed. If optimum speed (Vopt) is not available on the machine tool, select the highest speed (closest to Vopt) available on the machine and then find out fopt from Eq. (13) corresponding to this chosen speed. Further, selection of Vopt or fopt will be decided according to the type of operation, say, for finishing operation select high speed (maximum permitted) and low feed. For roughing operation, take maximum permitted feed and find out the optimum speed from Eq. (12).

Machine Tool Maximum Power Restriction

The cutting power may be expressed by

P = WVf α d β --------------- (16)

Where, P is cutting power, W, α and β are constants for a given tool-work combination.

If the values of selected speed and feed are such that the available cutting power is exceeded, then one or both must be reduced. It means a change moving the machining conditions away from the machining conditions for minimum cost. To make this change as small as possible, speed or feed should be adjusted by as little as is necessary to meet the power restriction. In other words, the maximum possible power should be used.

Now, put ∂C p/∂V= 0 to get optimum speed corresponding to the maximum power.

Similarly, find out optimum feed for maximum power (Pm) from ∂C p /∂f = 0.

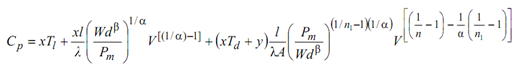

After substituting the value of f from limiting power Eq. (10.16) in Eq. (10.10), we get

------------------(17)

------------------(17)

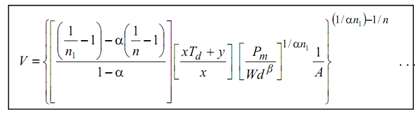

Differentiate Eq. (10.17) and equate to zero ∂C p/∂V = 0 . This leads to

--------- (10.18)

--------- (10.18)

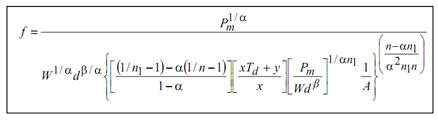

Now, follow the similar procedure as above to solve for ∂C p /∂f = 0 .

This leads to

---- (19)

---- (19)