Example of turning operation:

In a certain manufacturing company, a turning operation is performed under the following conditions:

Depth of cut = 0.00127 m, feed rate = 3.81 × 10-4 m / rev, work dia. = 76.2 × 10-3 m, axial length of cut = 0.1524 m, time required to load and unload components = 15 s/component, time required to change a tool = 4 min / tool. Average cost of reconditioning a worn tool is Rs. 2/- per cutting edge, machine operating cost is Rs. 10/hr, number of components required per year is 30,000. The average number of components produced is 620 at 330 RPM and 15 at 535 RPM during the life of tools for each speed.

Find annual minimum savings (if any) by modifying the drive to give some intermediate speed.

Solution

To solve the problem, the steps to be followed are as given below :

(1) Convert all the data in the same units as shown in step 1

(2) Two spindle speeds are given in the problem and the third speed (optimum speed) can be calculated. Using the cost per component at these three speeds, the minimum savings can be calculated using Eq. (1).

Here, some of the quantities like Tac and T are unknown.

(c) Calculate Tac and T for both the given speeds using Eq. (9).

Tac ≈ 1/fN

Tool life, T = time per component (Tac) × total number of components that can be produced.

(d) Now, optimum speed should be determined using the following equation

• Here, 1/n and B are unknown. They should be determined using the following relationship.

T = B/ V 1 / n

- T has been calculated (step (c)) for two speeds. Make two equations for T1 and T2 and then solve them to evaluate B and 1/n. Now, substitute the values of B and 1/n to determine optimum speed (or optimum spindle speed) from Eq. (12).

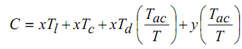

(e) Calculate cost per component for three cases (C1, C2 and C3) from Eq. (1) and then calculate the minimum savings per year.

Step 1

Given : d = 1.27 × 10-3 m, f = 3.81 × 10-4 m / rev, D = 76.2 × 10-3 m, l = 0.1524 m, Tl = ¼ min /comp, Td = 4 min per tool, y = Rs. 2/- per cutting edge = 200.0 paise per cutting edge, x = Rs 10/- per hour = 16.67 paise / min, N1 = 330 RPM, N2 = 535 RPM.