Remote Indication:

Remote indication is necessary to provide transmittal of vital level information to a central location, such as the control room, where all level information can be coordinated and evaluated. There are three major reasons for utilizing remote level indication:

Level measurements may be taken at locations far from the main facility The level to be controlled may be a long distance from the point of control The level being measured may be in an unsafe/radioactive area.

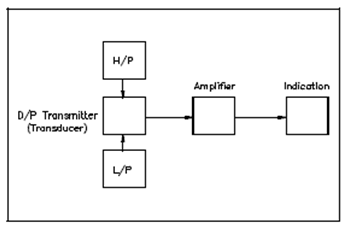

Figure illustrates a block diagram of a typical differential pressure detector. It consists of a differential pressure (D/P) transmitter (transducer), an amplifier, and level indication. The D/P transmitter consists of a diaphragm with the high pressure (H/P) and low pressure (L/P) inputs on opposite sides. As the differential pressure changes, the diaphragm will move. The transducer changes this mechanical motion into an electrical signal. The electrical signal generated by the transducer is then amplified and passed on to the level indicator for level indication at a remote location. Using relays, this system provides alarms on high and low level. It may also provide control functions such as repositioning a valve and protective features such as tripping a pump.

Figure: Block Diagram of a Differential Pressure Level Detection Circuit