Single-Pass Condensers:

After the steam condenses, the saturated liquid continues to transfer heat to the cooling water as it falls to the bottom of the hotwell, or condenser. This is known as subcooling, and a definite amount is desirable. A few degrees subcooling avoid condensate pump cavitation. The difference among the saturation temperature for the existing condenser vacuum and the temperature of the condensate is termed condensate depression. That is expressed as a number of degrees condensate depression or degrees subcooled. Excessive condensate depression reducing the operating effectiveness of the plant since the subcooled condensate have to be reheated in the boiler, that in turn needs more heat from the fossil fuel, reactor, or other heat source.

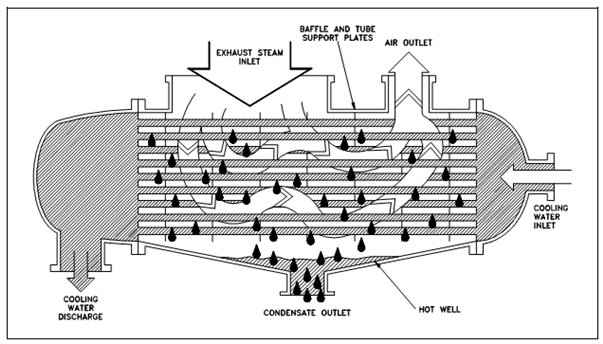

Figure: Single-Pass Condensers

There are various condenser designs, but the most general, at least in the large power generation facilities, is the straight-by, single-pass condenser described in above Figure. This condenser design gives cooling water flow by straight tubes from the inlet water box on one end, to the outlet water box on another end. The cooling water flows at one by the condenser and is termed a single pass. The separation among the water box fields and the steam condensing area is proficient through a tube sheet to that the cooling water tubes are attached. A cooling water tubes are supported inside the condenser through the tube support sheets.