Blank Development

Blank development is the first important stage which governs the strip layout and die stages. For axisymmetrical shapes, CAPP systems use analytical computation methods to determine the blank sizes from the final draw geometry .

The algorithms are based on the principle of constancy of volume between the blank and drawn cup, neglecting the material thinning/thickening during the deformation. The exact blank shapes are difficult to calculate as the material thinning/thickening varies due to material properties, heat treatment, punch/die geometry and surface texture. To account for these factors, some stock allowance is provided on the calculated blank sizes for subsequent trimming operations .

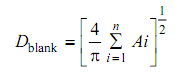

To compute the blank size, the drawn cup is broken down into standard shapes such as a Circle, Annular disc, Cone, Cylinder etc and the surface area of each primitive element is computed. The blank diameter is calculated as under

where Dblank = Blank Diameter , and

Ai = Area of primitive element i.