Kanban System:

Imagine a manufacturer gives a production schedule to the work centre. It is the work centre that sends the finished parts to the finished goods area. Imagine that the supervisor of the work centre ought to build fifty units of product on the same day. Then the supervisor checks the parts or raw materials available at hand and if he doesn't have the needed number of them he shall send a request to the previous work centre that supplies the part asking for the quantity needed for building the product. In this way system use to pull parts as well as subassemblies towards the work centre. In the Kanban system, work centre requests materials from other using a card called a Kanban.

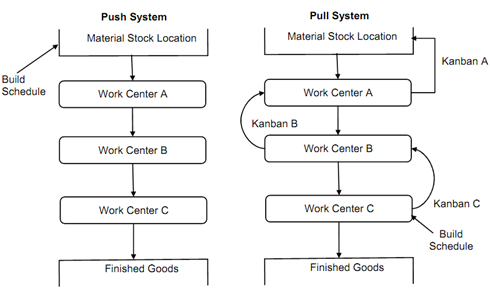

Figure illustrates the difference between pull and push system. The push system is a unidirectional process whereas the pull system is a double flow procedure. In a push system the build schedules and materials flow in the similar direction whereas in pull system materials travel in one of the direction while the build schedule travel in opposite direction. A Kanban system communicates the schedule from one work centre to another.

Figure: Material and Schedule Flow in Push and Pull System