JIT Application in Job Shops:

Traditionally, JIT is applied to line flows, but job shop environments also offer JIT benefits. The focus of JIT is product flow. Although job shops are characterized by low volume and high variety, JIT may be used if demand may be stabilized to permit repetitive manufacture. Stabilizing demand is usually easier to accomplish while the demand is from a downstream production stage instead of an end customer.

Factory machining centres, paints shops, and shirt making are instance of job-shop type operations that process parts and components before they reach final production stages.

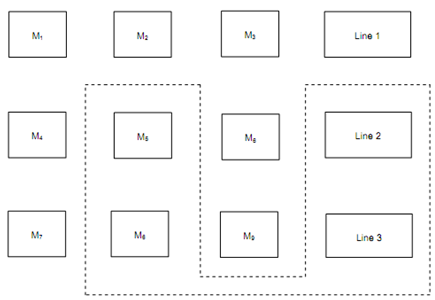

Figure: JIT in a Job Shop Layout Showing the Materials Handling Vehicle Route Connecting machine Centres and Line Operations

By way of instance, consider the production system in Figure. If a work centre produces nine different parts utilized by several product varieties that are produced just in time, the work centre keeps containers of completed output of all of the nine parts at the centre to be picked up by users. Operators could make periodic rounds throughout the facility to pick up blank containers and drop them off at the corresponding upstream work centre and to pick-up full containers. In Figure, automatic guided vehicles pick-up and deliver part numbers M5 and M8 to lines 2 and 3 for processing. These handling procedures can be manual or automated, but ways, these periodic pick-ups and drop-offs permit the system to operate in a just-in-time mode.