Sample injection port:

The common needs for an injection port are controlled temperature, low volume and inertness within construction. The temperature must be manage inside the proper range to vaporise all the solutes instantly but not too hot to cause thermal decomposition of labile solutes.

The whole injection port must also be swept along with carrier gas to ensure in which all of the vaporized solutes are moved rapidly within the column. This means in which its internal portion must be kept to a minimum volume. The materials of construction of the injection port should be such in which no reaction along with the solutes occurs. It must be as inert as much as probable to minimize any possibility of catalytic decomposition because of contact along with exposed surface area.

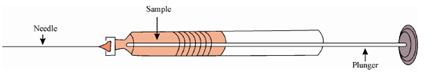

The syringes used to inject samples are commonly of small volumes. The general ranges are from zero to 1 microlitre, zero to 5 microlitres and zero to 10 microlitres. Within the one microlitre syringe, the sample is totally confined to the needle and could never be observed through the operator. For the other two syringes, the sample enters and its level could be directly measured within the barrel of the syringe. The barrel is calibrated within microlitres and fractions of microlitres.

Figure: Sampling syringe