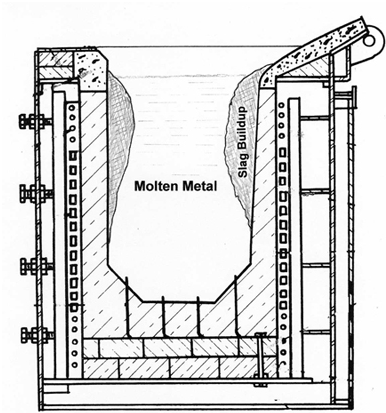

Coreless-Induction Furnace:

Coreless induction furnaces are utilized for smaller (5-10 ton) operations. Coreless furnaces are preferable where in this gas pickup and volatile metal alloy loss is a difficulty. Coreless melting furnaces utilized a refractory envelope to have the metal, and surround that by the copper coil, water-cooled. Operating on the similar basis as a transformer, the charge behaves as a single secondary turn, so generating heat through eddy current flow while power is applied to the multi- turn primary coil as illustrated in Figure 4(a). While the metal melts, these electromagnetic forces also generated a stirring action.

Figure : Coreless-Induction Furnace