Hydraulic Operation:

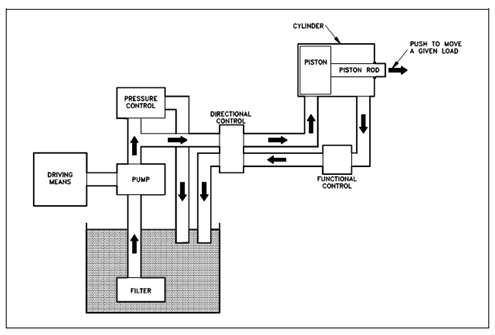

The operation of a classical hydraulic system is described in Figure. Oil from a tank or reservoir flows by a pipe within a pump. Frequently a filter is given on the pump suction to erase impurities from the oil. The pump, commonly a gear-type, positive displacement pump, could be driven through an air motor, electric motor, gas or steam turbine, or an internal combustion engine. A pump raises the pressure of the oil. An actual pressure developed depends upon the design of the system.

Most hydraulic systems have a few method of avoiding overpressure. As seen in Figure, one technique of pressure control includes returning hydraulic oil to the oil reservoir. A pressure control box displays on Figure is commonly a relief valve which gives a means of returning oil to the reservoir upon overpressurization.

Figure: Basic Hydraulic System

The high pressure oil flows by a control valve (directional control). Control valves modify the direction of oil flow, which depending upon the desired direction of the load. Within Figure the load could be moved to the left or to the right through modify the side of the piston to that the oil pressure is applied. The oil which enters the cylinder applies pressure over the area of the piston and developing a force on the piston rod. A force on the piston rod enables the movement of a load or device. The oil from another side of the piston returns to a reservoir or tank.