Magnetic Alloy Steels

These steels are divided into two groups. Those which retain their magnetism and those which do not. The steels that retain their magnetism are termed hard magnetic steels. The other group is magnetically soft.

1% plain carbon steel in its fully hardened condition was the earliest permanent magnetic material. Later developments occurred when W, Cr and cobalt were added as alloying elements. The most useful of permanent magnetic steels contain high proportions of Ni, Co, and Al, with small amount of W. Alnico is a good example which contains 10% Al, 18% Ni, 12% Co, 6% Cu, Rest Fe.

Magnetically soft materials are required to demagnetise quickly. In earlier days soft iron was used as a soft magnetic material but later iron-silicon alloys containing upto 4.5% Si were developed. However, modern high duty soft magnetic materials are iron-nickel alloys such as Permalloy which contains 78% Ni. Another soft magnetic material is mumetal containing 75% Ni. These alloys are used for transformer cores and as shield material for submarine cables.

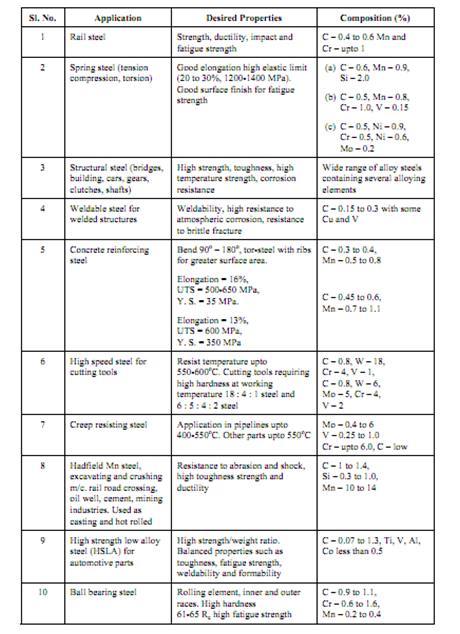

Alloy steels find a wide range of application and a few of them are described in Table

Table: Application of Alloy Steels