Normalising

Normalising is utilized as a finishing treatment for carbon steels giving higher strength than annealing. There is no serious loss of ductility also. In this procedure the heating and soaking is similar as in full annealing but part is allowed to cool in air so that cooling are much faster. The finer grains are produced because there is lesser time available for them to grow. The finer grain structure enhances the yield and final strengths, hardness & impact strength. The ductility is, though, slightly decreased.

The effect of small grain size is more noticeable in impact strength than in tensile strength at low carbon content, say 0.2%. The tensile strength develops only by 5% whereas impact strength might improve by as much as 20% by normalising than though annealing. At higher carbon content, say 0.4% C it is the impact strength only but also the tensile strength that improves marked by around 15%.

Normalising frequently applied to castings and forgings is stress relieving procedure. It increases strength of medium carbon steel to some extent. While applied to low carbon steel it develops machinability.

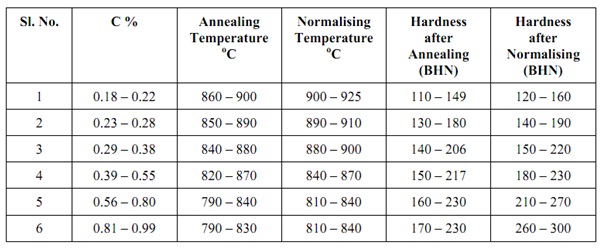

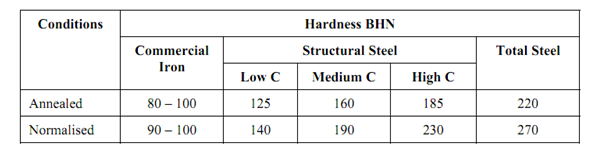

Alloy steels in which the austenite is very stable might be normalised to generate hard martensitic structure. Cooling in air produces high rate of cooling which might decompose the austenitic structures in such martensite and steels is generated. This increases the hardness to a great extent. Table (a) describes the hardness obtainable in several normalised steels. Table (b) describes variation of annealing & normalising temperature & resulting hardness for the different carbon contents of plain carbon steels.

Table : Hardness of Annealed and Normalised Carbon Steels

Table: Variation of Annealing and Normalising Temperature and Resulting

Hardness for Different Carbon Contents