Cooling Rate and Quenching Media

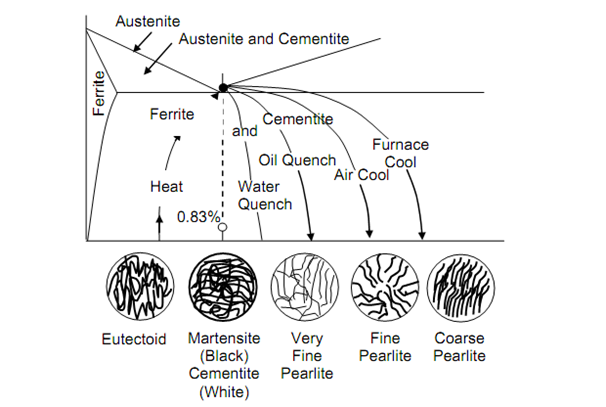

Rate of cooling plays a vital role in determining the ultimate structure after quenching in case of eutectoid steel. Figure schematically illustrates four different structures that are attained cooling rates when austenised steel is cooled up in four different media.

Figure: Mircostructure Resulting from Different Cooling Rates Applied to Austenitised Samples of Eutectoid Steel

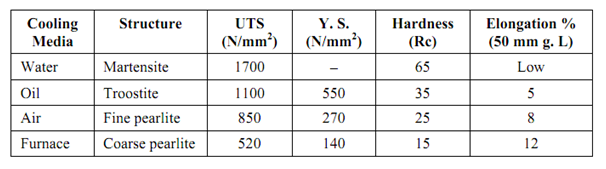

Only the drastic water quench generate a fully martensite structure. While quenched in oil the austensite transforms into very fine pearlite. Fine pearlite also results if the austenised eutectoid steel is air-cooled. Though, if permitted to cool in furnace coarse pearlite is formed. These effects have already been considered under the headings of annealing and normalising. Though, it might be mentioned that very fine pearlite structure that is obtained form oil quenching is named primary troostite. Table explained the effects of several cooling media on mechanical properties of eutectoid steels.

Table: Mechanical Properties of Eutectoid Steels after Cooling in Different Quenching Media

Water is the cheapest quench media for plain carbon steels. But, while using water care must be exercised that water is correctly agitated during this treatment otherwise air bubbles might be trapped on the surface and insulate the spots from which heat flow shall be delayed. Such spots shall develop softness. Salt water or brine is more severe quenching media as it removes heat faster. Though, in this case the steel should be thoroughly cleaned after quenching otherwise the surface start to rust. For very low carbon steels hydroxide solutions are frequently used instead of brine. If slower cooling rates are desired, the steel may be quenched in oil with high flash points. Several grades of quenching oil are available. High carbon steels are invariably quenched in oil since water quenching will develop cracks in such steels.