Temperature Profiles

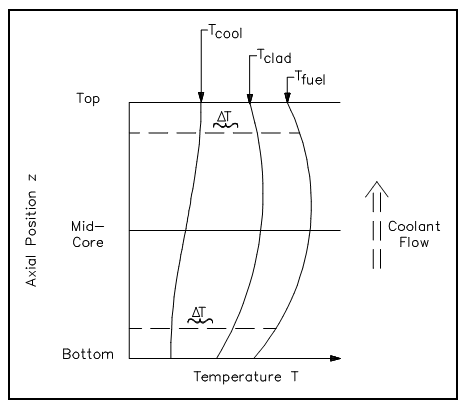

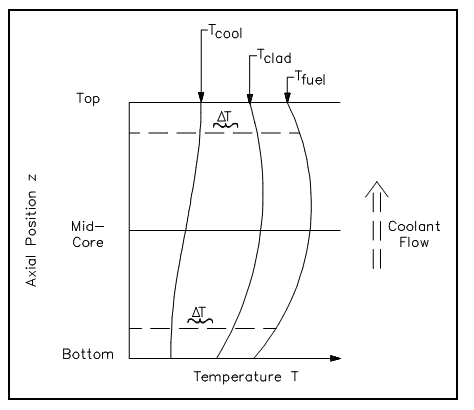

Additional regions of interest are the temperature profiles found in the core. The typical axial temperature profile all along a coolant channel for a pressurized water reactor (PWR) is shown in figure below. As would be predictable, the temperature of the coolant will rise throughout the whole length of the channel.

Figure: Axial Temperature Profile

Though, the rate of rise will differ all along with the linear heat flux of the channel. The linear heat rate and power density will obey the neutron flux shape. Though, the temperature distributions are skewed by the changing capacity of the coolant to eliminate the heat energy. As the coolant rises in temperature as it flows up the channel, the fuel cladding and, therefore, the fuel temperatures are high in the upper axial area of the core.

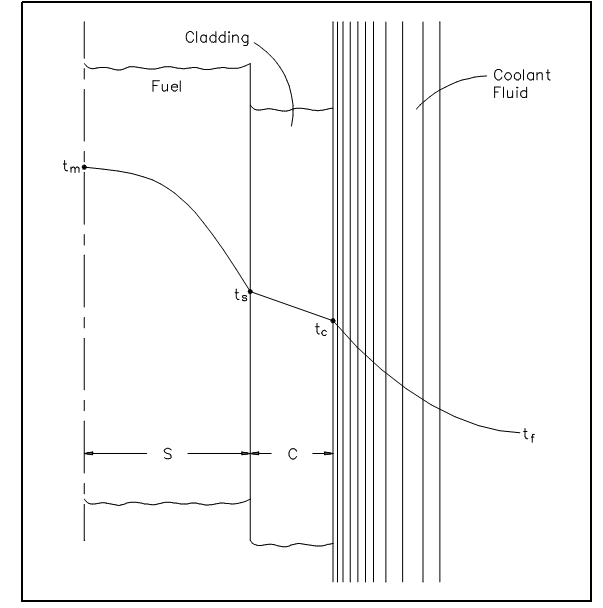

The radial temperature profile across a reactor core (supposing all channel coolant flows are equivalent) will fundamentally obey the radial power distribution. The regions with the highest heat production rate (power) will generate the most heat and have the maximum temperatures. A radial temperature profile for a separate fuel rod and coolant channel is shown in the figure below. The fundamental shape of the profile will be based upon the heat transfer coefficient of the different materials included. The temperature differential across each material will have to be adequate to transfer the heat formed. Thus, when we know the heat transfer coefficient for each material and the heat flux, we can compute peak fuel temperatures for a given coolant temperature.

Figure: Radial temperature profile across a fuel rod and coolant channel