Regenerative Heat Exchanger

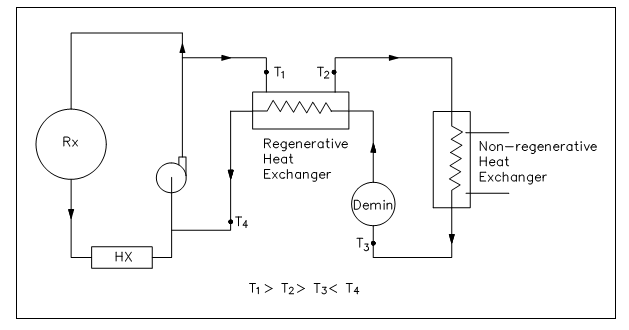

The regenerative heat exchanger usually uses the fluid from a dissimilar region of the similar system for both hot and cold fluids. An illustration of both regenerative and non-regenerative heat exchangers working in conjunction is generally found in the purification system of a reactor facility. The main coolant to be purified is drawn out of the primary system, passed via a regenerative heat exchanger, non-regenerative heat exchanger, and de-mineralizer, back via the regenerative heat exchanger, and revisited to the primary system (The figure is as shown below).

In the regenerative heat exchanger, the water returning to the main system is pre-heated by the water entering the purification system. This achieves two objectives. The first is to minimize the thermal stress in the primary system piping due to the cold temperature of the purified coolant being returned to the prime system.

The second is to decrease the temperature of the water entering the purification system previous to reaching the non-regenerative heat exchanger, permitting use of a smaller heat exchanger to achieve the preferred temperature for purification. The primary benefit of a regenerative heat exchanger application is conservation of system energy (which is, less loss of system energy due to the cooling of the fluid).

Figure: Regenerative Heat Exchanger