Parallel and Counter-Flow Designs

However ordinary heat exchangers might be extremely dissimilar in design and construction and might be of the single- or two-phase kind, their modes of operation and efficiency are largely established by the direction of the fluid flow inside the exchanger.

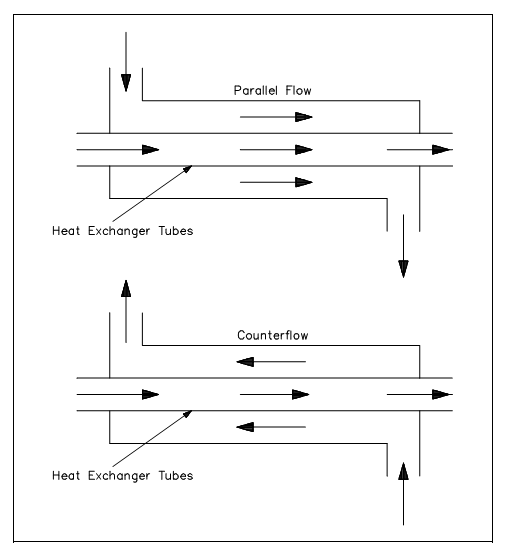

The most general arrangements for flow paths inside a heat exchanger are counter-flow and parallel flow. The counter-flow heat exchanger is one in which the direction of the flow of one of the functioning fluids is opposite to the direction to the flow of another fluid. In a parallel flow exchanger, both fluids in the heat exchanger flow in similar direction.

The figure below symbolizes the directions of fluid flow in the parallel and counter-flow exchangers. Under comparable situations, more heat is transferred in a counter-flow arrangement than in a parallel flow heat exchanger.

Figure: Fluid Flow direction

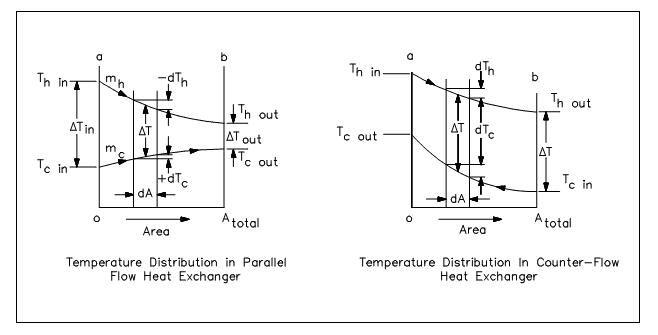

The temperature profile of the two heat exchangers point out two major drawbacks in the parallel-flow design. At first, the large temperature difference at the ends (the figure is as shown below) causes great thermal stresses. The opposite expansion and contraction of the building materials due to diverse fluid temperatures can lead to ultimate material failure. Secondly, the temperature of the cold fluid exiting the heat exchanger never surpasses the lowest temperature of the hot fluid. This association is a distinct drawback when the design purpose is to increase the temperature of the cold fluid.

Figure: Heat Exchanger Temperature Profiles

The design of a analogous flow heat exchanger is beneficial whenever two fluids are needed to be brought to nearly similar temperature.

The counter-flow heat exchanger has three important benefits over the parallel flow design. At first, the more uniform temperature difference among the two fluids reduces the thermal stresses during the exchanger. In second, the outlet temperature of the cold fluid can move toward the highest temperature of the hot fluid (i.e., the inlet temperature). Thirdly, the further uniform temperature difference generates a more uniform rate of heat transfer during the heat exchanger.

Whether parallel or counter-flow, heat transfer inside the heat exchanger includes both convection and conduction. One fluid (i.e., hot) convectively transfers heat to the tube wall where conduction occurs across the tube to the opposed wall. The heat is then convectively conveyed to the second fluid. Since this procedure occurs over the whole length of the exchanger, the temperature of fluids as they flow via the exchanger is not usually constant, though differs over the whole length, as pointed in figure shown below. The rate of heat transfer differs all along the length of the exchanger tubes since its value based upon the temperature difference among the hot and the cold fluid at the point being viewed.