Jominy Test

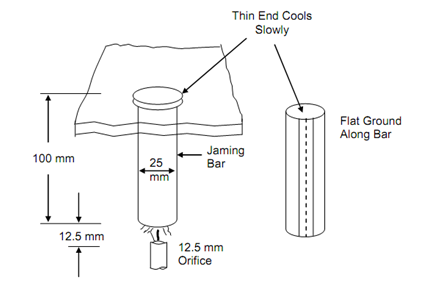

More convenient laboratory test for hardenability is Jominy test. A standard specimen of steel is austenised in normal manner. Then the lower end of the specimen is quenched by a standard jet of water, resulting into a varying rate of cooling.

Figure: The Jominy Test of Hardenability

The rate of cooling at the jet end is approx 300oC/sec while that at the other end is about 3oC/sec. This varying cooling rate produces a wised range of hardness along the length of Jominy specimen. A flat portion is ground along the length & hardness measured at several points. The plot of hardness along the length gives Jominy index of hardenability.

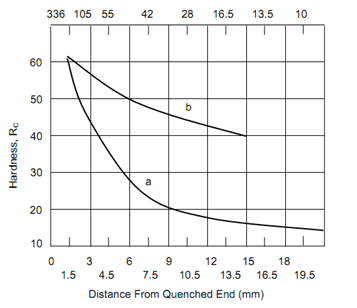

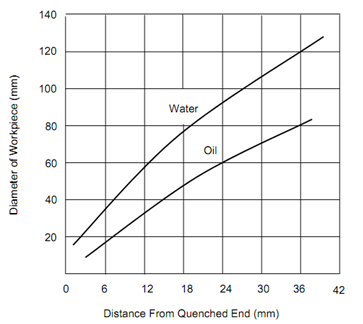

The best use of the Jominy curve is built by drawing a horizontal line corresponding to hardness of the semi-martensite zone. The hardness of semi-martensite zone is explained in Table. The point where this line needs the Jominy curve calculated the distance from the quenched end which might be inserted in Figure to determine the diameter for specific steel which shall be fully hardened in water or oil.

Figure: Hardenability Curves Plotted from End Quench Test Data

(a) For Shallow; and (b) For Deep Hardening Steel

Figure: Determining the Diameter of Fully Hardened Articles according to the Distance from the Quenched End

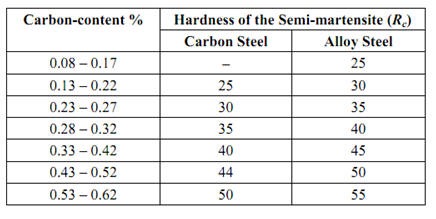

Table: Relationship between the Hardness of the Semi-Martensite Zone and the Carbon Content