Opitz System

The Opitz coding is most likely the best-known coding system. This was developed by H. Opitz of the Aachen Tech University in West Germany. The code utilizes a hybrid structure. However, except the first digit, it resembles a chain structure more nearly. This has following advantages over the existing system

- This is nonproprietary. It is broadly used.

- This provides fundamental framework for understanding the classification & coding procedure.

- This can be applied to machined parts, non-machined parts, & purchased parts.

- This considers both design & manufacturing information.

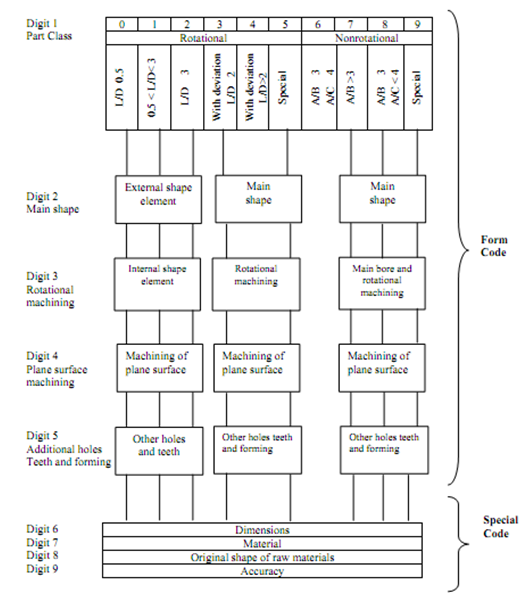

The Opitz code contains a form code and supplementary code. The form code might represent parts of the following variety: short, long, cubic, flat, rotational etc. A dimension ratio is further utilized in classifying the geometry: the length/diameter ratio is utilized to classify the rotational components and the length/height ratios are utilized to classify non-rotational components. The attributes of rotational parts are explained as shown in Table. The Opitz form code utilize five digits that focus on

(a) component class,

(b) basic shape,

(c) plane surface machining,

(d) rotational-surface machining,

(e) gear teeth, auxiliary holes & forming.

A supplementary code is a polycode consisting of four digits is generally appended to the Opitz system.

Figure: Basic Structure of Opitz Code