KK-3 System

The KK-3 system is one of the general-purpose classification & coding system for machined parts. This was developed by the Japanese Society for the encouragement of the machined industry.

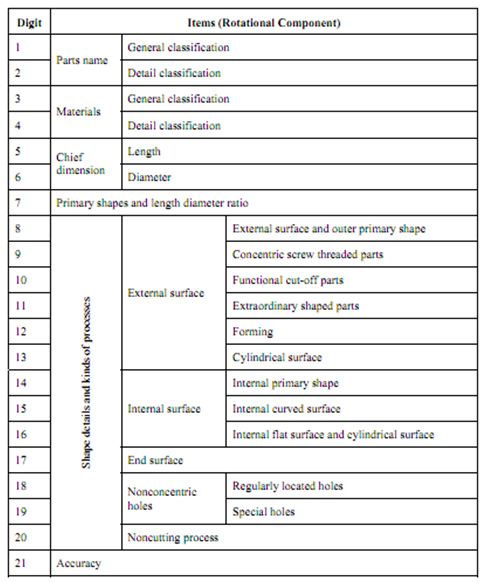

KK-3 was first presented in the year 1976 and uses a 21-digit decimal system. Table show the code structure for rational component. It might represent more information than that of optiz code due to greater length.

Table: Structure of the KK-3 Coding System (Rotational Components)

This includes two digits for component name or functional name classification. Primary digits classify the general function, such like shafts, gears, drive and moving parts, and fixing parts. The second digit explained more detailed function such as bevel gears, worm gears, spur gears, and so on.

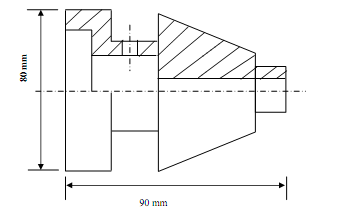

KK 3 also classifies materials by using two-code digit. The primary digit classifies material type & second digit classifies shape of the raw material. Length, length/diameter and diameter ratios are classified for rotational components. Shape details & types of processes are classified by using 13 digits of code. Finally one digit is needed for accuracy presentation. An example of coding a component by using KK-3 is illustrated in Figure and Table.

Figure: A Machine Part