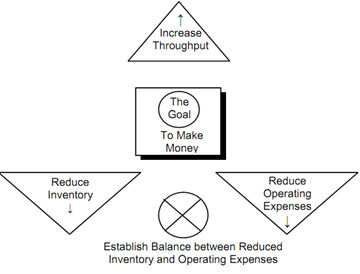

Managing Inventory and Operating Expenses:

Synchronous manufacturing calls for following :

a. Increased throughput requirements.

b. Manage inventory and production expenses.

Increased throughput means better (fast and smooth) flow of material. But, inventory and production cost are inversely associated. When inventory increases, the operational expenses can reduce. For instance, to reduce the operational expenses, we can decide to go for large batch-size and fewer set-ups. But what shall be the effect on inventory? The work in procedure inventory will begin building up. (Note down that in JIT, we go for smaller batch-size and more set-ups). On the other hand, low inventory causes higher operational expenses, Now, the next question is : what may be the lowest limit of batch-size? It is one item per batch (like, ideal JIT system), in which the inventory, is minimum. However, this system of one item per batch will have highest possible batch-processing and thus will lead to very high operating cost. Hence, there is a need to manage the inventory and operating expenses so that their cumulative effect is minimum at a high throughput.

Figure: Three Elements of The Goal