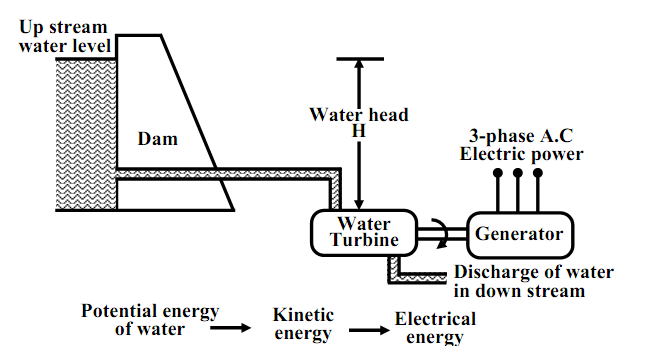

Hydel plants

In a hydel power station, water head is employed to drive water turbine coupled to the generator. Water head might be available in hilly area naturally in the form of water reservoir (i.e., lakes and so on.) at the hill tops. The potential energy of water can be employed to drive the turbo generator set installed at the base of the hills via piping termed as pen stock. Water head might also be formed artificially by manufacturing dams on an appropriate river. In contrary to a thermal plant, hydel power plants are environment-friendly, precise and clean as no fuel is to be burnt to generate electricity. Whereas running cost of these plants is low, the preliminary installation cost is instead high as compared to thermal plants due to massive civil construction essential. Also sites to be chosen for such plants based upon natural availability of water reservoirs at hill tops or availability of appropriate rivers for manufacturing dams. Water turbines usually operate at low rpm; therefore number of poles of the alternator is high. For illustration a 20-pole alternator the rpm of the turbine is merely 300 rpm.

Figure: Basic components of a hydel generating unit.