Comparison of Cycloidal Profile Teeth with Involutes Profile Teeth:

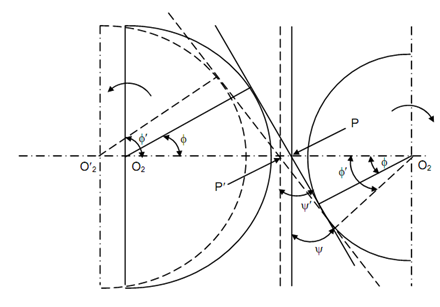

Even if the two pitch circles do not touches each other because of inaccuracy in fitting of the two gears or, the law of gearing shall still be followed in case of involutes profile. Given fig shows this situation. Now the centre of rotation of gear 2 is at O2′. The common normal to the two involutes at the point of contact shall be new common tangent to the two displaced base circles and its intersection along line of centres will be at P′. Because of increase in centre distance, the pressure angle shall increase slightly as illustrated in the figure. It is one of the reasons that involutes profile is universally utilized for gears. It may be cut along ease and pressure angle remains constant during the engagement. While it is not so in case of cycloidal profile teeth. The cycloidal teeth need very accurate fitting so that pitch circles touch each other that may not be always possible practically without a skilled worker and instruments.

The cycloidal profile tooth is built up of two curves but involutes tooth is built up of a single curve. Because of the simplicity of manufacturing and standardisation, the use of involutes teeth has become universal. Just one cutter or tool is needed to manufacturer a full set of interchangeable involutes gears. The cutter can be in the form of rack that results in low cost of manufacturing. The cycloidal teeth are very strong at the root.