Force Analysis in Spur Gears:

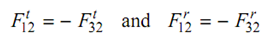

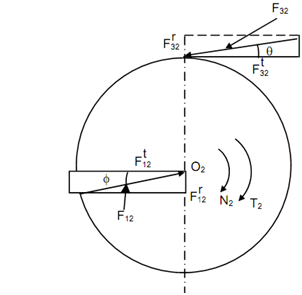

In the spur gears the teeth are aligned parallel to the gear axis. Assume a simple gear train consisting two gears only as illustrated in Figure 1(i). The gears are illustrates by the pitch circles of gears. The power is transmitted through pinion 2 to gear 3. Torque acting on pinion 2 refers T2 and speed is N2. The sense of T2 and N2 are illustrated in the diagram. The speed of gear 3 is considered as N3. As the pinion is the driver, so, the sense of torque and speed will be the same.

Figure 1(ii) shows the free body diagrams of gear and pinion. Both pinion and gear are subjected to two forces. These two forces must be equal and parallel is magnitude. The couple produced by these two forces must be equal to the torque applied on the pinion in magnitude however opposite in action.

The tooth load on the gear and pinion are F23 and F32, respectively. These forces are also equivalent in magnitude however opposite in direction. The line of action of these forces will be along the common normal that is inclined to the common tangent to the pitch circles through the pressure angle 'φ'. The gear is driven through the pinion. The gear is subjected to the load torque T3. The reaction at the hinge of the gear will be equivalent in magnitude to the tooth load however opposite in direction. The couple produced by these two forces will be equal to the load torque T3 on gear 3.

(i) (ii)

Figure 1 : Simple Spur Gear Train

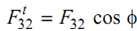

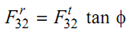

The tooth load on the pinion might be resolved along the radial and tangential directions as shown in Figure 2.

Figure 2 : Components of Tooth Load

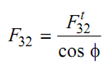

The tangential component is

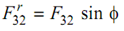

and, radial component is

In practice, power at the driving gear is known. With the help of specified speed, torque 'T2' on the gear may be found out. From the teeth and module pitch circle radius may be calculated as

Here 't2' & 'm' are respectively number of teeth & module.

Along the help of torque 'T2' tangential component of tooth load may be estimated.

. . . (1)

. . . (1)

. . . (2)

. . . (2)

. . . (3)

. . . (3)

Likewise, the reaction force at the hinge may be estimated.