Furnace Charging:

The primary step in the production of any heat is to choose the grade of steel to be built up. Preparation of the charge bucket is significant operation, not just to ensure correct melt-in chemistry however also to ensure good melting conditions. The scrap should be layered in the bucket according to size & density to promote the quick formation of a liquid pool of steel in the hearth when providing protection for the roof and sidewalls from electric arc radiation. Other considerations involve minimization of scrap cave-ins that can break electrodes & ensuring that big heavy pieces of scrap do not directly lie in front of burner ports that would result in blow-back of the flame onto the water cooled panels. The charge might include carbon and lime or these might be injected into the furnace throughout the heat. Various operations add some carbon and lime in the scrap bucket and supplement this along injection.

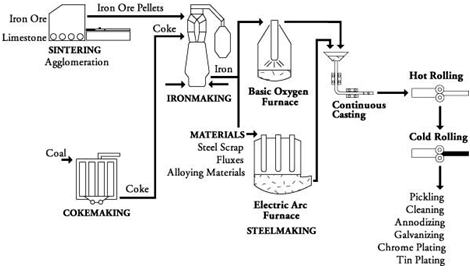

Figure: Steelmaking in Electric Arc Furnace

The roof & electrodes are grow and are swung to the side of the furnace to permit the scrap charging crane to move a complete bucket of scrap into place over the furnace. Usually the bucket bottom is a clam shell design that means the bucket opens by retracting two segments on the bottom of the bucket. The scrap falls into the furnace and the scrap crane eliminates the scrap bucket. The electrodes swing and roof back into place over the furnace. The roof is lowered and the electrodes are then lowered to strike an arc on the scrap. This commences the melting portion of the cycle. The number of charge buckets of scrap needed to generate a heat of steel is dependent mainly on the volume of the furnace and the scrap density. Most of the modern furnaces are designed to operate along a minimum of back-charges. It is advantageous because charging is a dead-time where the furnace does not contain power on and so is not melting. Minimizing these dead-times helps to maximize the productivity of the furnace. Additionally, energy is lost each time the furnace roof is opened.