De-slagging:

De-slagging operations are carried out to eliminate impurities from the furnace. Throughout and refining and melting operations, some of the undesirable materials in the bath are oxidized and enter the slag phase.

This is advantageous to eliminate as much phosphorus into the slag as early in the heat as possible (that means while the bath temperature is still low). The furnace is tilted backwards & slag is poured out of the furnace through the slag door. Elimination of the slag eliminates the possibility of phosphorus reversion.

Throughout slag foaming operations, carbon might be injected into the slag where it shall reduce FeO to metallic iron and in the procedure produce carbon monoxide that helps foam the slag.

C + FeO = CO + Fe

If the high phosphorus slag has not been removed prior to this operation, phosphorus reversion shall occur. Throughout slag foaming, slag might overflow the level in the EAF and flow out of the slag door.

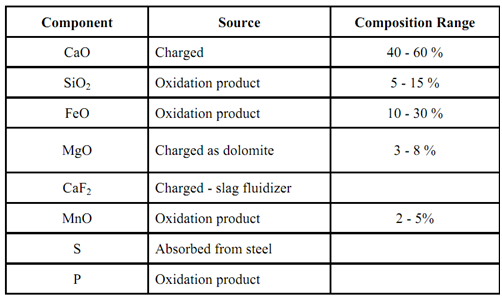

The following table illustrated the typical constituents of an EAF slag :