Inspection Accuracy

There are normally two errors committed on the part of manufacturers while carrying out the inspection. These two kinds of mistake are called Type I and Type II errors. Type I error occurs when a good lot is rejected and is called producers risk. Type II error occurs when a bad lot is accepted and is called consumers risk. An error is committed by the inspector that misses some of the defect during inspection of an assembly line.

In manual inspection, these errors result from factors such as :

- Complexity & difficulty incurred when performing an inspection task.

- Inherent variations in the inspection procedure.

- Requirement of judgment by the human inspector.

- Mental fatigue.

- Inaccuracies or problems with the gages or measuring instruments utilized in the inspection procedure.

After establishing methodology for an automated system, inspection errors occur because of factors such as:

- Complexity and difficulty of the inspection task.

- Resolution of the inspection sensors affected by "gain" and similar control parameters setting.

- Malfunctioning of equipments.

- Faults or "bugs" in the computer program controlling the inspection procedure.

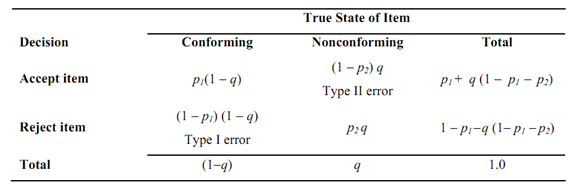

The capability of the inspection process to ignore these types of errors is termed as inspection accuracy. Inspection accuracy is high while few or no errors are committed. Drury (1992) recommended measures of inspection accuracy for the case in which parts are classified by an inspector (or automatic inspection system) into either of two categories, conforming or nonconforming. Letting this binary case, let p1 be the probability equivalent to the correct decisions. Therefore (1-p1) is the probability that a conforming item is classified as nonconforming (Type I error). Likewise, if p2 is probability that a nonconforming item is classified as nonconforming then, (1-p2) is the probability that a nonconforming item is classified as conforming (Type II error).

Assume q be the actual fraction defect rate in the batch of items. A table of possible outcomes may be constructed as shown in Table to reveal the fraction of parts classified correctly & incorrectly and those incorrectly classified, whether the error is Type I and Type II.

Empirically, these proportions (probabilities) would be assessed for specific inspectors by finding the proportion of correct decisions made in each of the two cases of nonconforming and conforming items in parts batch of interest. Unluckily, the proportions differ for different inspection tasks. Generally the more difficult inspection tasks have high error rates (p1 and p2 values are lower). Also, p1 and p2 rates are different for different inspectors. Typical values of p1 ranges among 0.9 and 0.99 and that of p2 among 0.80 and 0.90, but values as low as 0.50 for both p1 & p2 have also been reported (Drury 1992). p1 is inclined to be higher than p2 for human inspectors since inspectors are generally on the lookout for defects and examining good quality.

Table of Possible Outcomes in Inspection Procedure, Specified q, p1 and p2

For an automated inspection system or human inspector, the workable measures of inspection accuracy are the values of p1 & p2. The values of p1 & p2 are expected to vary independently to some degree based on the inspection task & system performing the inspection and therefore provide some very useful information. Nevertheless, simple average may be taken to combine the two values into a single measure of inspection accuracy.

A = (p1 + p2)/2

Where,

A = measure of inspection accuracy that ranges among zero (all inspection decision incorrect) & 1.0 (all decisions correct = perfect accuracy);

p1 = probability that a conforming item is classified as confirmed; and

p2 = probability that a defective item is classified as defective, as previously defined.

A practical problem in applying the measure is finding the true values of p1 and p2. Another inspection procedure must to be applied to determine these values resulting in further cropping up of similar errors as in the first procedure whose accuracy is being assessed.