Workabilty For Different Conditions:

It is clear from the previous discussion that the workability being a complex property is difficult to define precisely. It is rather more hard to quantify the workability that is why different methods of determining workability quantify this property in their own way, such as slump (in mm), compaction factor (in terms of decimal fraction), Vee-Bee time (in seconds), flow (in %), etc. Under these circumstances, it is equally difficult to decide the requirement of workability in terms of above parameters for various types of works.

There are several factors, which govern the choice of workability namely, shape and size of section, amount of reinforcement, type of compacting equipment available, time of placing, temperature, etc. Generally greater workability is required for the following conditions:

(a) For hand compaction as compared to machine compaction.

(b) For heavily reinforced sections as compared to less densely sections.

(c) For thin sections as compared to thick sections.

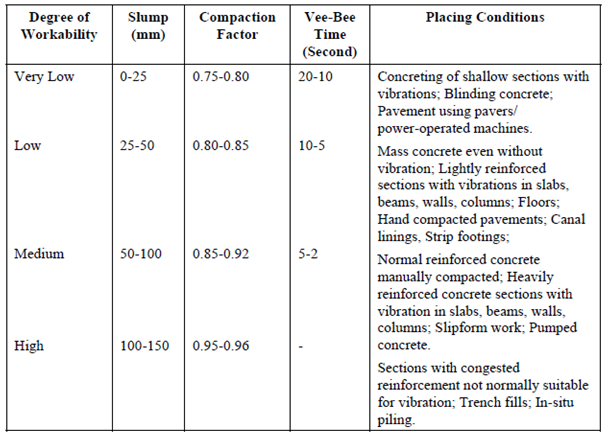

Table: Suggested Values of Workability for Different Placing Conditions (For 20-40 mm Maximum Size of Aggregate)

In view of the above, we can conclude that for any type of work the concrete mix should have the minimum possible workability so as to achieve satisfactory and maximum compaction. However, as a guideline, Table 1 can be referred to find out the relative workability for various types of works/conditions.