Use of production planning:

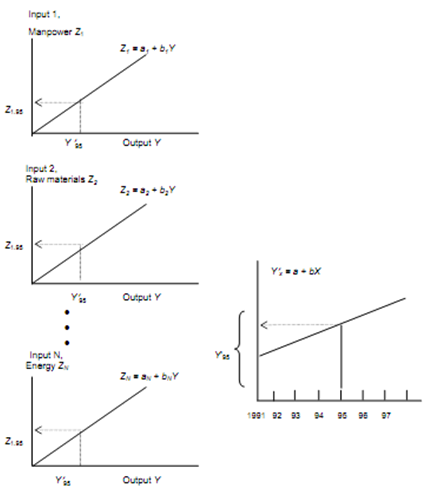

For the use of production planning, the demand forecast for output units is converted into a set of requirements for materials, labour-hours of desired skills, machine-hours of different types of equipment, energy, etc. This conversion mainly depends on the stability of product design. For the products whose characteristics remain relatively stable from period to period, statistical relationships (e.g. regression equations) can be developed relating output volume to input requirements, as illustrated in Figure. These relationships can be used to convert a given forecast of demand for the items into estimates for the input requirements.

For products whose designs change frequently due to fashion trends, technological innovations, or other factors, this method of statistical extrapolation is not applicable. The conversion, in this case, is carried out by using the bill of materials, which has the input requirements for materials of each design style in matrix form. Use is also made of standard data, by which it is possible to estimate the man-hours and machine hours required to produce an item from the raw material. Therefore, once a forecast for a given design is obtained, the input requirements are computed using the bill of materials and the standard data.

For selecting the length of planning period for a forecast, we must know the system's reaction time, also called lead time, to changes in some key characteristic and the frequency with which such decisions are considered, that means management review time.

The lead time includes the time to make a decision whether any change is required and the time to implement the decision. To be changed, different production inputs need different lead times. For instance, adding a new model to the already existing range of clock models can require 2 years (time for reaching the decision, completing the design, getting the dies and tooling, installing equipment, etc.).

Figure: Converting Final Demand into Input Requirements for Products(s) with Stable Design

Management review time depends on company's policy as to how often should certain changes be desired. The hiring of casual labour may be reviewed on a weekly or even daily basis, but decisions related to capacity expansion may be considered 2 or 3 years after the most recent addition. As a general rule, a forecast must cover a period at least equal to the lead time plus the review time for the production input or capacity change under consideration.