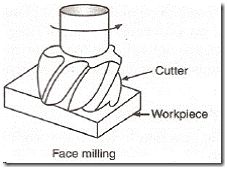

Face Milling:

Figure 5(b) illustrated the cross section of the undeformed chip genrated during symmetrical face milling (Figure b) of previous unit and Figure a. It is supposed that just a single tooth is engaged in machining. For a milling cutter along D as diameter, workpiece width like W, and feed per tooth as ft, the undeformed chip thickness (tu) at any location of the cutter might be evaluated as follows:

Figure a: Face Milling Cutting in Operation

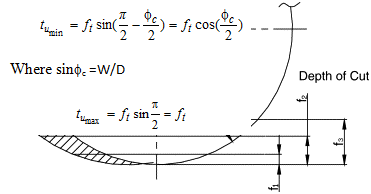

Figure b: Cross-section of the Chip Produced during Face Milling

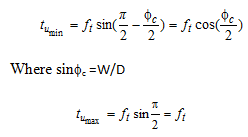

For the geometry illustrated in Figure, the undeformed thickness (t) of the chip at an angle Φ is provided by

tu = ft sinΦ

The minimum and maximum values of 'tu' would occur at  and Φ=P/2, respectively.

and Φ=P/2, respectively.

In order to evaluate the mean undeformed chip thickness integrate the chip thickness expression among the upper limit and lower limit of Φ, and divide the similar by the total angle of tooth engagement, Φc .

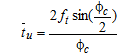

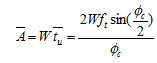

Hence, the mean undeformed chip thickness ( ) is provided by following

-----------------------(33)

-----------------------(33)

The approximate mean cross-sectional area of the chip might be calculated by using the following equation.

------------------- (34)

------------------- (34)

(To be more accurate, W must be replaced by the mean arc length[{(D-ft)/2)} Φc], where Φc is in radians.)