Steam Flow Detection

The Steam flow detection is generally accomplished by the use of a steam flow nozzle.

DESCRIBE density compensation of a steam flow instrument to involve the reason density compensation is needed and the parameters used.

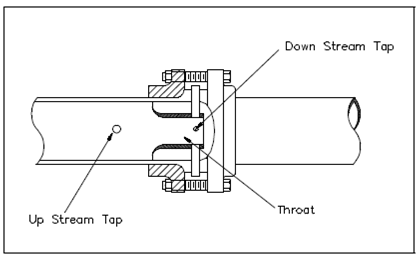

The flow nozzle is generally used for the measurement of steam flow and other high velocity fluid flow measurements where erosion might occur. It is capable of measuring around 60% higher flow rates than an orifice plate along with the similar diameter. This is due to the streamlined contour of the throat that is a distinct benefit for the measurement of high velocity fluids. A flow nozzle needs less straight run piping than an orifice plate. Therefore, the pressure drop is about the same for both. A classical flow nozzle is display in Figure.

Figure: Flow Nozzle

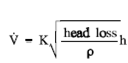

Because steam is considered to be a gas, modifications in pressure and temperature greatly affect its density. Given Equations 1 and 2 list the fundamental relationship for volumetric flow and mass flow.

(1)

(1)

and

(2)

(2)

where

v' = volumetric flow

K = constant relating to the ratio of pipe to orifice

h = differential pressure

ρ = density

m' = mass flow

It is quite possible to substitute for density within the relationship by using Equation 3.

Ρ =pm/Rθ (3)

where

ρ= density

p = upstream pressure

m = molecular weight of the gas

θ= absolute temperature

R = gas constant

Through substituting for density, the values are used through the electronic circuit to calculate the density automatically. Because steam temperature is associatively constant in most steam systems, upstream pressure is the just variable in the above equation which changes as the system operates. Measuring the system pressure is all which is needed for the electronics to calculate the fluid's density if the other variables are hardwired.