Control of FMS System

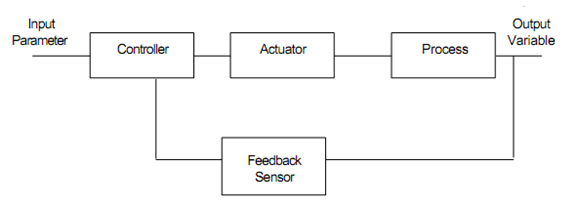

The FMS includes a distributed computer system that is associated to the work stations, material handling system & other hardware components. A typical FMS computer system contains a central computer & microcomputers controlling the individual machines & other components. The control system in FMS causes the procedure to accomplish its defined function. The control might be either closed loop or open loop. A closed loop control system is one in which the output variable is compared with an input parameter and any difference among the two is utilized to drive the output into agreement with the input. This is also known as feedback control system. A closed loop control system consists of six basic elements which is illustrated in Figure.

Figure: A Feedback Control System

Here, the controller compares the output value with the input and makes the needed adjustment in the process to decrease the difference between them, which is accomplished by actuators. Actuators are the hardware devices which physically carried out the control actions such as electric fan, an electric motor. A sensor is utilized to measure the output variable and closed the loop between input and output.

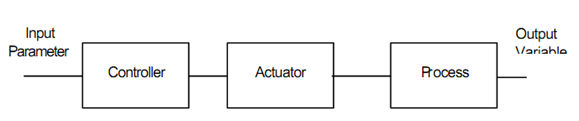

In contrast to the closed loop control system an open loop operates without the feedback loop as shown in given figure.

Its advantage is that generally it is simpler & lesser expensive than a closed loop system. Open loop system is generally appropriate to use when

- The actions taken by the control system are simple,

- The actuating function is very reliable, and

- Any reaction forces opposing the actuation are negligible to effect the actuation.

Figure: An Open Loop Control System