Definitions for FMS

Based on the above logic and trend the FMS have been developed. Some typical definitions for FMS are:

- A series of items of fabrication equipment or automatic machine tools connect together with an automatic material handling system, regular hierarchical digital pre-programmed computer control, and provision for random fabrication of parts or assemblies that fall in predetermined families.

- A FMS is a highly automated GT machine cell, having a group of processing work stations (normally CNC machine tools), interconnected through an automated material handling and storage system, and controlled through a distributed computer system. (Groover)

- FMS combines mechanical and microelectronics engineering to bring the economies of scale to batch work. A specific central online computer controls the machine tools, other workstations, & the transfer of tooling and components. The computer also provides and information and monitoring control. This combination of flexibility and total control makes possible the production of a broad range of products in small numbers.

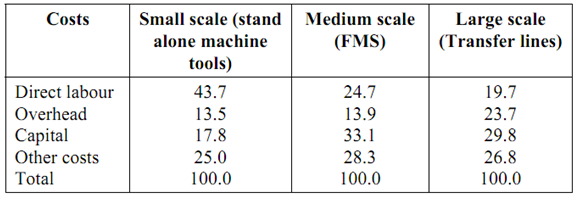

Therefore, it can be seen that a true FMS may handle a wide variety of dissimilar parts, generating them in small numbers even one at a time, in any order, as required by making use of all of the computer controlled equipment (workstations and material handling and storage) with the help of a central computer with a distributed control of all of the equipment within. Typical costs linked with the several types of manufacturing systems are given in Table 2.

Table 2: Typical Costs attached with Various Manufacturing Systems