Elongation Index:

Aggregate is termed as elongated when its greatest dimension (i.e. length) is reasonably large relative to its mean dimension. The amount of elongation is denoted by elongation index.

Elongation index is given as the percentage by weight of particles in the sample of aggregate whose greatest dimension (i.e. length) is greater than 9/5 times of their mean dimension (i.e. mean sieve size fraction to which the particle belongs).

For example, if we have aggregate sample of 20 mm mean size then any particle of this sample having its length greater than 36 mm [i.e. (9/5) × 20] will be designated as elongated aggregate. The elongation index is applicable to particles of size 6.3 mm or greater.

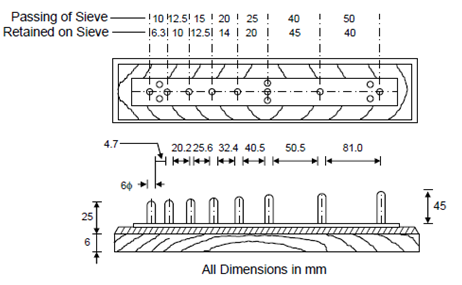

It is measured with the help of standard metal length gauge as shown in Figure 3 and as described in IS 2386(Part I) : 1963. The length gauge has apertures of various sizes. A sample of aggregate is taken and sieved through a set of sieves ranging from 63 mm to 6.3 mm and particles of every fraction are collected separately. The aggregate sample should be taken within enough quantity so that each fraction sample should have at least 200 particles. Now, particles of each fraction are allowed to pass through the corresponding aperture individually.

The elongation index is computed as below:

Elongation Index = Weight of particles retained on the length gauge/ Total weight of the sample × 100

Figure: Length Gauge (For Determining Elongation Index)

Comments

The presence of elongated, blade-shaped or flaky particles, both in coarse and fine aggregates, should be prevented. It could be restricted to 15-20 % by weight of total aggregate for normal concrete. The presence of such type of particles adversely affects the strength of concrete as they act as a weak- link within the gel structure of concrete. The surface area to volume ratio for such type of particles is high, that adversely affect the workability of concrete mix.