Lube Oil Cooler Temperature Control System:

The controlled outcome is the quantity or condition of the plant that is controlled. That signal represents the controlled variable.

The feedback signal is a function of the outcome signal. It is sent to the summing point and algebraically added to the reference input signal to acquire the actuating signal.

The actuating signal represents the control action of the control loop and is equivalent to the algebraic sum of the reference input signal and feedback signal. This is also known as the "error signal."

A manipulated variable is the variable of the procedure acted upon to manage the plant outcome (controlled variable) at the desired value.

A disturbance is an undesirable input signal which upsets the value of the controlled outcome of the plant.

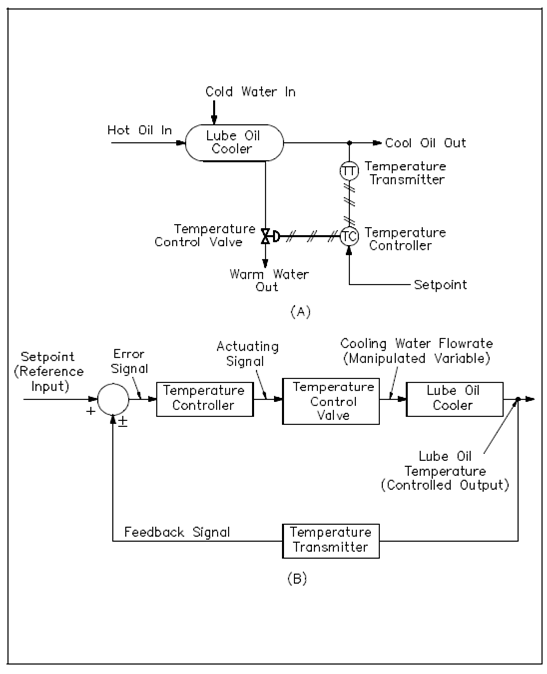

Below figure displays a classical application of a block diagram to identify the operation of a temperature control system for lubricating oil. (A) in Figure displays a schematic diagram of the lube oil cooler and its associated temperature control system.

Figure: Lube Oil Cooler Temperature Control System and Equivalent Block Diagram

Lubricating oil reduces friction among moving mechanical categories and also removes heat from the parts. As a conclusion, the oil becomes hot. That heat is erased from the lube oil through a cooler to avoid both breakdown of the oil and damage to the mechanical components it serves.

The lube oil cooler consists of a hollow shell along with various tubes running through it. The Cooling water flows within the shell of the cooler and around the outside of the tubes. Lube oil flows within the tubes. The water and lube oil never creates physical contact.

It picks up heat from the lube oil through the tubes as the water flows through the shell side of the cooler. This cools the lube oil and warms the cooling water as it leaves the cooler.

The lube oil must be managed inside a specific operating band to ensure optimum equipment performance. This is completed through controlling the flow rate of the cooling water along with a temperature control loop.