Excavation

For little buildings, excavation is carried out manually through means of pick axes, crowbars, spades and etc. In case of big buildings and deep excavation, mechanical earth cutting equipment could be used.

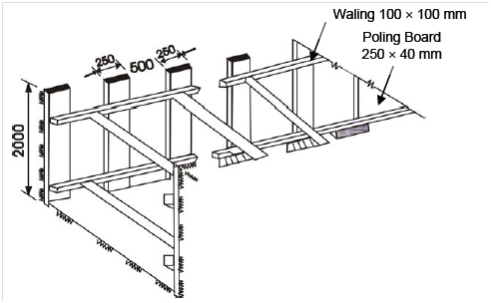

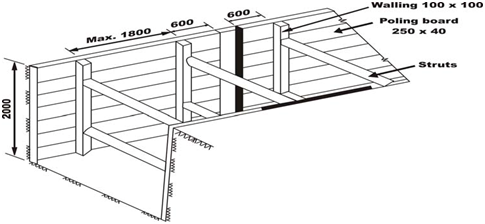

For hard soils while the depth of excavation is less than 1.5 m, the sides of the trench do not required any external support. If the soil is loose and the excavation is deeper, a few sort of shoring is required to support the sides from falling. Planking and strutting could be intermittent or continuous depending on the nature of soil and the depth of excavation. In that case of intermittent or "open" planking and strutting the whole sides of trenches are not covered. Vertical boards (called as poling boards) of size 250 × 40 mm of the needed length could be placed along with gaps of about 50 cm (Figure 4). These shall be remain apart through horizontal waling of strong timber of section 100 × 100 mm at a minimum spacing of 1.2 m and strutted through a cross piece of 100 × 100 square or 100 mm diameter. In that case of soft soils continuous or "close" planking is adopted and the vertical boards are remaining touching every other without any gap as display in Figure 5(a).

Figure 4: Open Planking

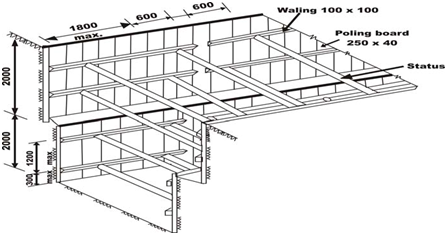

If the soil is extremely soft and loose, the boards should be placed horizontally against the sides of the excavation and supported through vertical waling boards that shall be strutted to same timber pieces on the opposite side of the trench as display in Figure 5(b).

Care has to be taken although withdrawing the timber members after completion of the foundation work, so in which there is no collapse of the trench.

Construction of foundation below the subsoil water level poses problems of water logging. It is, thus, extremely frequent essential to dewater the area of excavation. Various operations have to be carried out inside the excavation, such as laying bed concrete, lying of RCC raft slab and construction of masonry etc. Thus, work could be carried out more efficiently if the excavation area is kept dry. To remain the area of excavation dry, water table should be managed at least 0.5 m below the bottom of an excavation. There are various methods available for lowering the water table. Information acquired from site and soil investigation would be meaningful in deciding the most suitable and economical technique of dewatering. Intended for fairly dense soil and shallow excavations, the easiest method is to have drains along the edges of the excavation and collect water within sumps and remove it through bailing or pumping. This is the most economical technique and is feasible of being executed with unskilled labor and extremely easy equipment.

a) Close Planking

b) Planking in Very Soft and Loose Soil

Figure 5

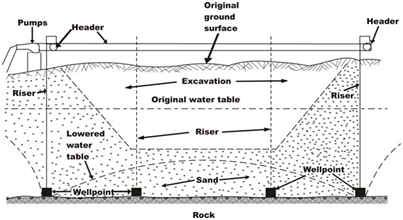

Where large excavations like as for rafts are to be dewatered, well point system could be employed. Well point consists of a perforated pipe and 120 cm long and 4 cm in diameter along with a valve to regulate flow and a screen to avoid entry of mud etc. These well points are installed along the periphery of the excavation at the needed depth and spaced at about 1m. The exact spacing could be decided on the basis of the categories of soil. Well points are surrounded through sand gravel filter and have riser pipes of 5 to 7.5 cm diameter. These pipes are linked to a header pipe that is attached to a high capacity suction pump. The ground water is drawn out through the pumping action and is discharged away from the site of excavation as display in Figure 6.

Figure 6: Lowering Water Table by Well Point