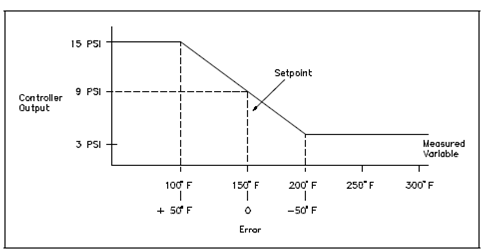

Controller Characteristic Curve:

The reason of this system is to give hot water at a setpoint of 150oF. The system must be capable of handling demand disturbances which could result in the outlet temperature increasing or decreasing from the setpoint. For this reason, the controller is set up such like the system functions as display in Figure.

Figure: Controller Characteristic Curve

A positive error is developed and the control valve opens additional if the measured variable drops below the setpoint. If the measured variable goes above the setpoint, a negative error is established, and the control valve throttles down (opening is decrease). The 50% proportional band causes full stroke of the valve among a +50oF error and a -50oF error.

While the error equals zero, the controller gives a 50%, or 9 psi, signal to the control valve. Since the error goes above and below this point, the controller generates an outcome which is proportional to the magnitude of the error, determined through the value of the proportional band. A control valve is then capable of being positioned to compensate for the demand disturbances which could cause the procedure to deviate from the setpoint in either direction.