Heat Transfer in Evaporators:

The three heat-transfer resistances in evaporators are:

(1) Refrigerant side for the shift of heat from solid surface to the liquid refrigerant.

(2) Metal wall.

(3) Cooled-medium side that could be because of water, air, brine or any other fluid or a wetted surface on a cooling & dehumidifying coil.

The heat transmit from solid surface to the evaporating refrigerant is of prime interest here. Though, the mechanism of boiling i so difficult due to the influence of such factors like saturation temperature, surface tension, latent heat and nature of the solid surface, as well as to the usual transport properties, that this is very complex to predict the heat-transfer coefficient analytically. Nevertheless, no effort is made here to present correlations applicable to evaporating refrigerants that are available in the big amount of published information provided on the subject.

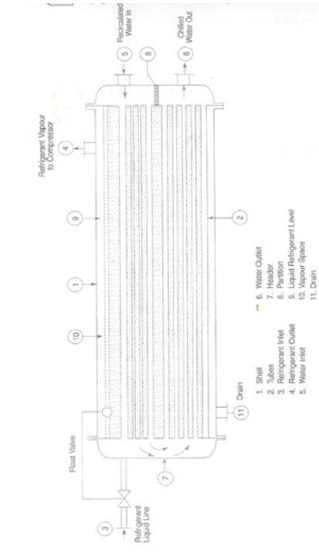

In commercial equipment, the boiling procedure occurs in two kinds of situations: one, of pool boiling like in flooded evaporators having refrigerant boiling the shell- side & the other, of flow or forced convection boiling like in direct- expansion evaporators along refrigerant on the tube-side.

Flooded Evaporator