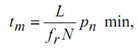

Machining time for turning operation:

Machining time for turning operation under the specified cutting conditions might be determined as follows. In turning, suppose tm is the machining time, l is the length to be turned, L is the total tool travel in the feed direction, fr is the feed rate per revolution and N is the rotational speed. After that, the relationships might be expressed as

----------- (4(a))

----------- (4(a))

L = l + y + Δ .------------- (4(b))

here, y refer tool approach, Δ refer over travel, if any, and pn is number of passes. pn based upon the machining allowance, Am (or the thickness of the material to be machined). Typically, in the last pass (or finishing pass) the depth of cut (d) is smaller than the roughing pass. But, if it is similar for all passes (Figure 5(b)) after that

pn = Am / d ----------- (4(c))

Hence, total machining time might be evaluated from

-------------- (4(d))

-------------- (4(d))

If finish machining allowance is to be let separately, after that number of passes might be evaluated from the equation that following :

.---------- (4(e))

.---------- (4(e))

Here, Af is finishing allowance, & df is depth of cut in final pass. Last value of pn must always be an integer number. Therefore, it is evident from Equation (4(d)) that by decreasing y, and Am, or by enhancing d, fr and N, the total machining time might be decreased or the productivity might be increased.