Tempering

The hardening treatment given to steel enhances the hardness but introduces internal stresses due to different cooling rates. The internal stresses are also built because of transformation from austenite to martensite. Tempering treatment aims at decreasing these stresses. The treatment consists in heating the hardened component to among 200oC and 600oC and holding it at that temperature for a predetermined period of time and then cooling gradually to room temperature. Since martensite itself is metastable phase, structural changes induced by tempering proceed quite rapidly. All of structures resulting from tempering are termed martensite. The changes occurring throughout various temperature ranges are described below :

100oC– 220oC

Very little change takes place in the micro-structure. Though, this heating helps eliminate considerable amount of internal stresses. The stress relieving treatment is given while maximum hardness is desirable and brittleness is not a problem. The strain is relieved due to removal of carbon atoms from their trapped positions.

240oC– 400oC

In this range martensite decomposes quickly into emulsified form of pearlite known as secondary troostite. This material is extremely fine in nature and hence provides good shock resistance. The fine edge tools are tempered in this range but more precisely within 270oC-300oC.

400oC – 550oC

The precipitate troostite starts to coalesce forming a coarser from of globular pearlite known as sorbite. It might be recalled both troostite and sorbite are preferably called tempered martensite now. This treatment is desirable in such components as springs, beams and axles.

600oC– 700oC

Heating hardened steel in this range causes spheroidisation, the structure being called as spheroidite. This structure is composed due to further coalescence of the carbide in the alloy. Spheroidised steels illustrated fairly good machinability since the hard carbide particles are embedded in the soft ferrite matrix & consequently do not ought to be cut by the cutting tool. If the spheroidised steel is heated to just above its lower critical temperature the pearlite present shall alter to austenite and cooling to room temperature shall yield a structure of lamellar pearlite plus pro-eutectoid ferrite or cementite based upon carbon content.

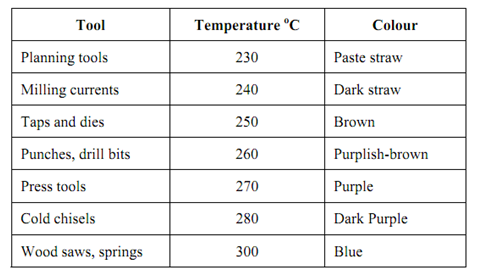

Judging the temperature of tempering by colour appearance is a tradition that is helpful on shop floors. Though, for accuracy the exact temperature measurement are to be preferred. Table explained the colour appearance & temperature in connection with several tools.

Table: Tempering Temperature and Colours of Tools