Magnesium And Its Alloys

Magnesium is a light metal with density of 1.74 g/cm3. Magnesium is much costlier than aluminium (density 2.74 g/cm3) with which it compares for lightness. Magnesium in its molten state burns readily, hence it is difficult to cast the alloys of magnesium. Magnesium alloys have low corrosion resistance and show poor fatigue and creep behaviour. Their h. c. p. structure does not permit to deform readily at room temperature since only three slip systems exist in h. c. p. at room temperature. The best advantage that magnesium alloys offer is that of low density and many aircraft parts are made in these alloys.

Al when added to Mg in the range of 3 to 10% with small amounts of Zn and Mn increases strength, hardness and castability. Addition of Mn (1.2%) with small amount of C does not increase strength but improves corrosion resistance. Mg-Al-Zn alloys have good mechanical strength and corrosion resistance. These alloys are good casting material and generally used at high temperature like 250oC.

Extrusions and forgings for general purpose are made in these alloys are used in aircraft, automotive, radio and instrument industries.

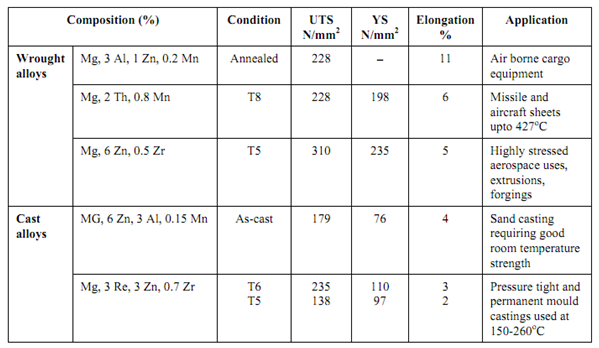

Some magnesium alloys are described in Table along with their applications.

Table: Magnesium Alloys